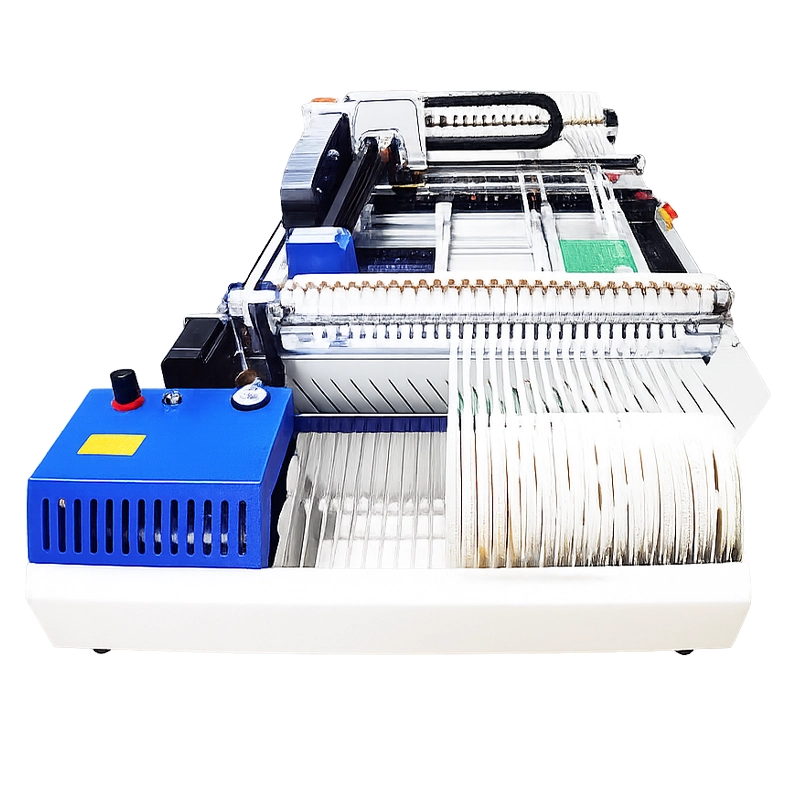

SMT Pick and Place

Pick and Place | SMT Assembly Machine

- The Pick and Place Machine is a high-precision, desktop pick and place machine designed for fast and efficient SMD (Surface-Mount Device) assembly.

- Equipped with dual placement heads, a high-resolution CCD vision system, and support for up to 54 tape feeders, this machine offers exceptional performance for small to medium production lines, R&D departments, prototyping labs, and educational institutions.

Speed

- Theoretical max: 6,500 pcs/hour

- Normal SMT speed: ~5,000 pcs/h

- Visual inspection speed: ~3,500 pcs/h

PCB size

- Minimum: 10 × 10 mm

- Maximum: 320 × 450 mm (or sometimes 320 × 220 mm)

Dimensions and Weight

- Machine: ~990 × 730 × 375 mm

- Feeder rack: ~235 × 700 × 245 mm

- Packed: ~1,190 × 850 × 560 mm; net ~60 kg, gross ~90 kg

Features

- Ideal for small- to medium-batch SMT production, R&D prototyping, experimental / teaching environments.

- Supports a wide range of components—passives, LEDs, and ICs up to BGA size.

- Two heads with dual-camera calibration improve efficiency and accuracy.

| Item | Details |

| Primary Application | Small to medium-batch SMT production, R&D prototyping, educational/testing use |

| Head Type | Dual-head with dual-camera calibration |

| Placement Accuracy | ±0.025 mm |

| Placement Speed | Up to 6,500 components/hour (typical ~5,000 cph) |

| Supported Components | Passive (0402–1206), LEDs (3014, 5050), ICs (SOP, QFN, BGA) |

| Supported PCB Size | Min: 10×10 mm / Max: 320×450 mm |

| Feeder Capacity | Up to 54 tape feeders + optional vibration feeders |

| Vision System | 4 CCD cameras (1 board + 3 component cameras) |

| Software & OS | Windows 7 with custom software, supports CSV / TXT file input |

| Air Supply Requirement | 0.4 MPa working pressure, vacuum up to –92 kPa |

| Power Consumption | 230 W (AC 220V – 50 Hz) |

| Machine Dimensions | Approx. 990 × 730 × 375 mm |

| Net / Gross Weight | 60 kg / 90 kg |

There are no reviews yet.